In early December last year, we announced that we were working towards improving our FORS accreditation from Silver to Gold Standard.

So we’re delighted to have recently been informed that after months of hard work, we have finally been awarded the coveted accreditation. We are now recognised FORS Gold Operators (ID Number: 007606).

The Fleet Operator Recognition Scheme (FORS) is a completely voluntary accreditation scheme that promotes best practice for commercial vehicle operators like ourselves.

It encompasses all aspects of Fleet Management, Vehicle Management, Driver Responsibility and Operations. It does this by encouraging and training fleet operators to measure, monitor and improve their overall performance.

HR & Safety Manager, Myriam Wiszniewski, commented:

“This is a fantastic achievement for

We hope that it goes some way to reassuring our customers and suppliers that we are deadly serious when we say that we aim to be the best in the business.”

We are looking to recruit an experienced Personnel Officer at our Goldthorpe depot.

Click the link below to access the full job description:

A Warm Welcome To Our New National Render Manager

Given our recent decision to add external r ender products & ancillary items to our product portfolio, we’re delighted to welcome on board our latest team member, Paul James, who has taken on the role of National Render Manager.

ender products & ancillary items to our product portfolio, we’re delighted to welcome on board our latest team member, Paul James, who has taken on the role of National Render Manager.

Paul has worked in the external render industry for over 13 years and brings with him a whole host of skills and expertise.

His primary role will be to tap into those rendering contractors who are sick and tired of poor service and who are looking for quicker, more reliable deliveries of the products they’ve come to know, like and trust.

Our aim is to become the UK’s No1 render distributor in 2019. And we are confident we can make this happen. Customer service is something we excel in at TEKFLOOR, and given that we have our own fleet of vehicles travelling to all four corners of the country on a regular basis, we can offer a speedy delivery service, often beating the turnaround of product manufacturers.

So, if you have an immediate render requirement – call Paul directly on 07375 451564 or you can also contact the sales team on 01709 261007.

– experienced HGV2 driver – class 2 driving jobs – cambridgeshire – day cab driver – driving vacancies – cambridge – HGV2 driving jobs – huntingdon –

>> CLICK HERE FOR A MORE DETAILED JOB SPECIFICATION <<

Keracem Eco is an ecologically-friendly, hydraulic mineral binder with normal-setting and rapid-drying properties.

Keracem Eco is an ecologically-friendly, hydraulic mineral binder with normal-setting and rapid-drying properties.

Ideal for high-performance screeds and heat-radiant slabs.

When mixed with inert materials of assorted grain size from 0 to 8mm, Keracem Eco creates screeds of high dimensional and constant moisture stability.

The rapid set allows the safe laying of ceramic tiles after 24 hours and hardwood floors after just 5 days.

The perfect product to use in GreenBuilding, can be recycled as an inert material at the end of its life.

IN STOCK NOW!!! Call us on 01709 261 007 for more details.

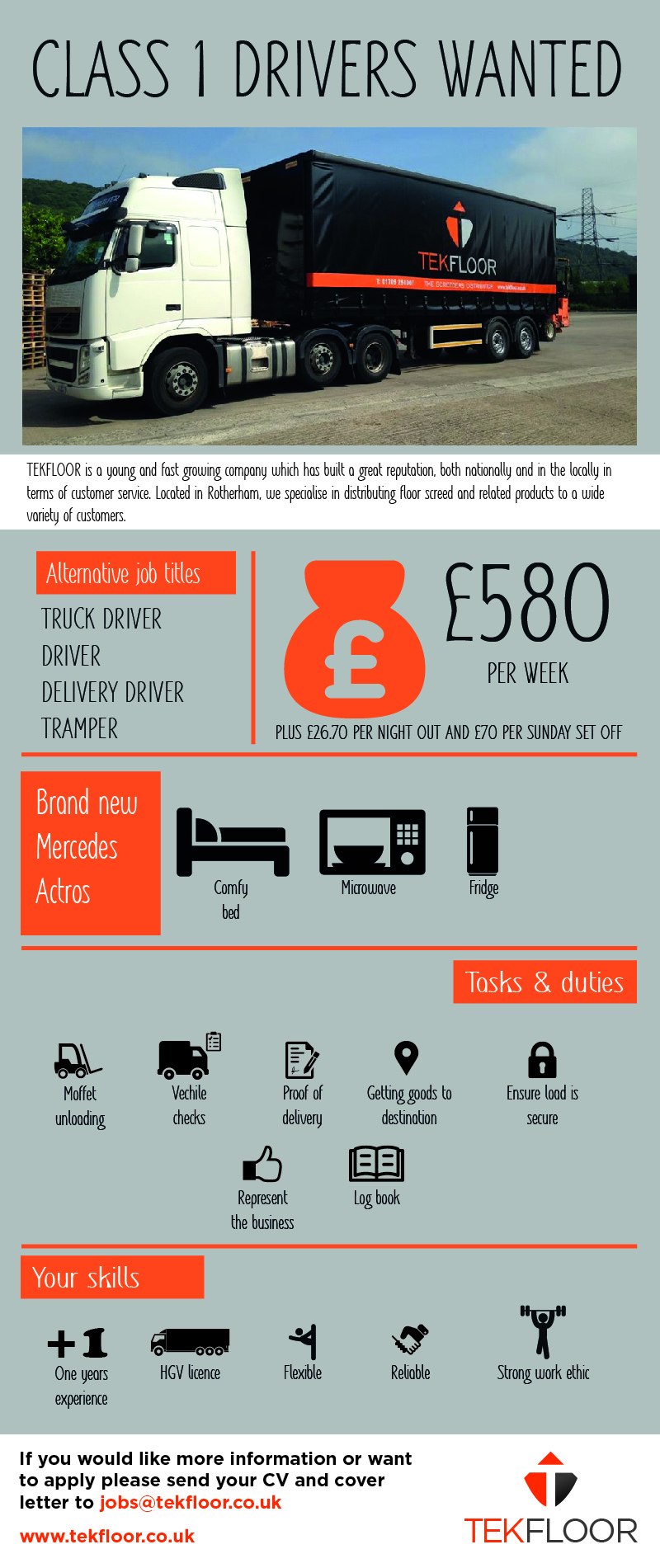

We’re on the look-out for Class 1 drivers, head over to our jobs page to apply for the role. We have created this infographic to highlight what we are offering with the role.

We are proud to announce that we are now FORS silver accredited! To find out more about the FORS silver accreditation, visit their website.

If you’re new into the world of screeding – you may be wondering what the difference between a screed and concrete is! After all, they do essentially have the same ingredients – cement, aggregates and water. So what makes them different?

In simple terms the key difference is this:

Concrete has the potential to hit a very high strength. A screed is used simply, as a top layer or finish.

How do I tell the difference before they set?

One of the key differences between concrete and screed is the texture. This isn’t something that many people will notice initially – or be able to measure to the untrained eye.

Concrete has a rougher texture than screed because it contains aggregate and stones – as well as sand and cement. These small stones are typically 20mm or less and are easily visable in the concrete when it is liquid. This is what makes concrete the stronger material.

Screed is a type of mortar. It is a smoother mixture made from sand and cement, a soil-type substance and it does not have the gravelly aggregate, the maximum grain size is around 4mm for a dry screed. This allows for a finer grain appearance when compared to concrete in its liquid form.

It’s been laid already! How do I tell the difference now?

If the surface has already been laid and the surface has hardened, the texture may not be easy to determine. You will need to look at the method used to lay it and the location of the material to make an educated guess.

Screed is most commonly used as a finishing layer on internal floors, with a thickness of around 50mm to 100mm.

If the surface was laid using floats – it is probably concrete. Concrete is usually laid much thicker, a minimum thickness is 100mm is recommended for domestic use and up to double that thickness for areas which have heavy footfall.

Concrete and screed can both be used for flooring and with underfloor heating – but it is highly unlikely that a DIYer would lay concrete in their home without the help of a professional.

A lot of modern homes do have polished concrete and this is something which can be purchased in a pre-polished state.

Getting concrete advice

Additives, commonly known in the trade as admixtures, are materials which can be added either before or during the mixing process to alter its properties. Admixtures can allow for various functions of the product depending on the requirements of each individual job. The admixtures can be categories within their functions to include bonding, shrinkage reduction and damp proofing.

Using admixtures can help when laying either concrete or screed. They can do a number of different things such as speed the setting time up. Fibres can be added to the screed to help reduce the cracking and retarder to give you more time to work with the screed.

At Tekfloor we would be happy to advise any concerns you may have about the concrete or screed – please contact us and speak to one of our technical experts.