It’s no secret that the PIR insulation market has been under significant strain for several months.

The key chemical needed for the manufacture of the high-performance insulant is still in drastically short supply, and there is currently no sign of the situation improving in the short term.

For this reason, PIR and phenolic manufacturers across the globe – not just in the UK – are experiencing severe production issues which have created a market-wide PIR and phenolic shortage, extended lead times and significant double-digit price increases.

Always ready to accept a good technical challenge, Rotherham based flooring and screeding specialists, TEKFLOOR Limited, have come up with a unique solution that is enabling their customer base to speed ahead with their flooring contracts despite the insulation material shortages.

TEKFLOOR’s Joint Managing Director, Steve Foster said, “Although there are other insulation manufacturers out there that are offering thicker EPS solutions to achieve the desired u-values, these results in increased floor zone thicknesses that make the work of secondary trades that much more difficult.

TEKFLOOR’s Joint Managing Director, Steve Foster said, “Although there are other insulation manufacturers out there that are offering thicker EPS solutions to achieve the desired u-values, these results in increased floor zone thicknesses that make the work of secondary trades that much more difficult.

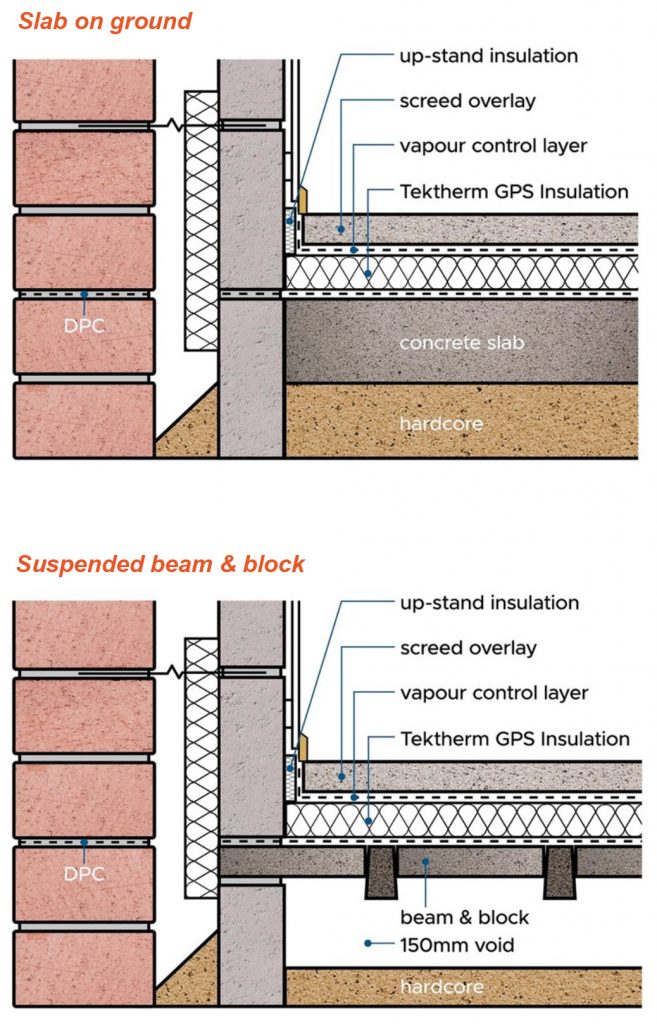

“At TEKFLOOR, we have come up with the perfect alternative and our TEKWARM GPS system is helping to combat the issues the industry is facing. So much so that we are being inundated with enquiries from architects, specifiers and screeding contractors who are looking for an alternative solution.

Steve went on to say that he had literally just put the phone down after speaking to a representative of one of the UK’s largest domestic housebuilders, who was desperately trying to source stocks of 60mm PIR for an impending flooring contract.

Specifying a TEKWARM alternative

“The specification the Client was working to was based on 60mm phenolic floor insulation (at 120kPa compressive strength) with a 75mm sand and cement screed. This gave an overall system thickness of 135mm.

“The specification the Client was working to was based on 60mm phenolic floor insulation (at 120kPa compressive strength) with a 75mm sand and cement screed. This gave an overall system thickness of 135mm.

“We advised them that should they be in a position to modify the specification, we could provide an alternative system comprising 100mm TEKWARM GPS150 insulation and a 35mm floating screed containing our TEKCEM DURASCREED hardening additive. This would give them exactly the same 135mm overall system thickness.”

Since TEKWARM GPS150 graphite enhanced insulation boards have a much greater compressive strength than phenolic or PIR (150kPa as opposed to 120kPa), at increased thicknesses, they can still meet specified U-Values.

However, with an increase in insulation thickness, careful consideration needs to be given to the screed layer, to keep the thickness of the floor zone within certain tolerances.

“And this is where the magic happens” enthused Steve. “By adding our TEKCEM DURASCREED hardening additive to a sand and cement screed at 35mm thickness, the screed would still achieve a standard working load of ≥2.0kN/m2 and a flexural strength of 7N/mm2, with the added benefit of significantly reducing the drying time of the floor as the screed is laid thinner.

“The end result means that the client has a floor zone that matches the overall thickness and u-value requirement of the existing specification, with the added benefit of product availability and enhanced screed drying times.”

“The end result means that the client has a floor zone that matches the overall thickness and u-value requirement of the existing specification, with the added benefit of product availability and enhanced screed drying times.”

All components of the TEKWARM GPS system are available from TEKFLOOR’s distribution depots in Rotherham and Huntingdon.

For further information, customers can contact us on 03300 555227 or email [email protected]